|

Titanium Cup Bangle |

| |

|

Ok, so these is not ground

breaking techniques, but this is how I do it. Keep in mind that this works for

me and might not necessarily work exactly the same for you. Having said that,

you are welcome to use this information as you wish and you also welcome to

e-mail me with any questions. |

|

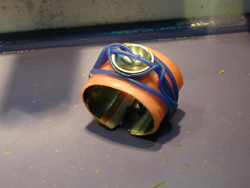

I use pink dental wax as my base

layer for all bangles of this type. 1.7mm thick… I love the stuff, especially

when you work under hot lights. It becomes almost like putty and you can mould

it and form it really easy. The blue is wax wire 8 gauge or about 3.5mm in

diameter. |

|

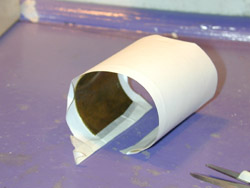

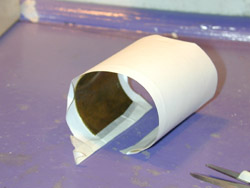

I made a Brass mandrel bigger than the shape of the bangle that I want. The

reason is that it is always easier to size something down than

up…. I tape paper around the brass mandrel and then I …. |

|

Gently file the excess off. |

|

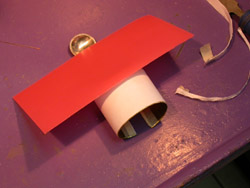

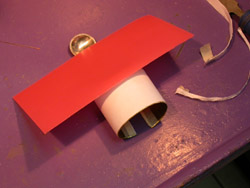

The pink Dental wax sheet is

then slightly warmed under a light and is formed over the mandrel.

|

|

The Titanium cup is pierced out of plate and formed to the shape that you

want. This is a cup, but it could be anything your good friend with a

hydraulic press can make for you. Also, I like to finish the titanium to a

high degree, and even get it to the colour that I want, because I remove it

from the wax before I cast. In the old days I used to cast it in place, but

unless the design calls for that, I don’t anymore. It is a major, major

mission to finish titanium off after it has been in the burn-out oven. This

is not to say that it can’t be done. By definition the blue colour which is

brought on by heat is subject to wear. So normally it has to be recessed or

protected in some manner. |

|

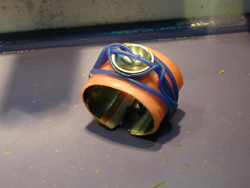

The first wax wire holding the whole catastrophe in place (grin)

|

|

Lots more wax wire. All the

outer wax wires are fused onto the pink wax. The reason for this is because,

if you don’t the plaster gets in between and causes a lousy join between the

two waxes. That leads to lots of fixing up, or even rejection.

|

|

Side note: I use one of those trigger electric solder guns. I have modified

the bit and replaced it with fine silver wire. I know, it’s heavy, clumsy,

cheap and nasty, but it supplies heat in industrial quantities…and in short

bursts. |

|

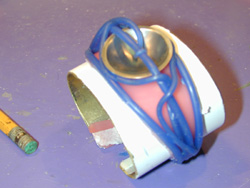

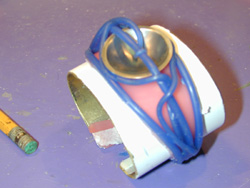

Cutting away the excess wax |

|

Now I have cut away the excess wax and when I remove the tape at the bottom

of the mandrel, the paper slides off without the wax sticking to it. It is

then easy to peal the paper off from the inside without damaging or bending

the wax. I sprue up and cast…

and finish off the Bangle |

|

The titanium gets polished and rouged and the cleaned to medical standards.

If it has but one spot of dirt on it, it will leave an imperfection on the

surface. Then I heat it with a bushy flame—SLOWLY, until I have the right

colour.

Then I quench in water, as this stops the

colouring process without affecting the hue. |

|

Final product---and sold to a really cool guy in the

Music bizzz!!!!! Yeah…. |